Pumping systems

High reliability equipment ready to work

Our pumping sets are characterized by having the perfect combination of functionality, reliability and sustainability at a very competitive price. A good proof of this is the more than 50,000 equipment sold in the last few years.

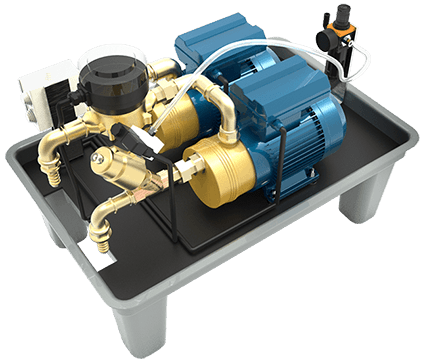

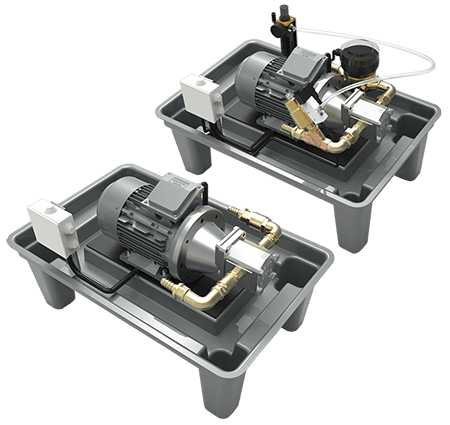

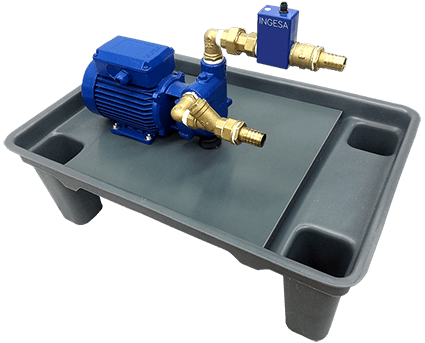

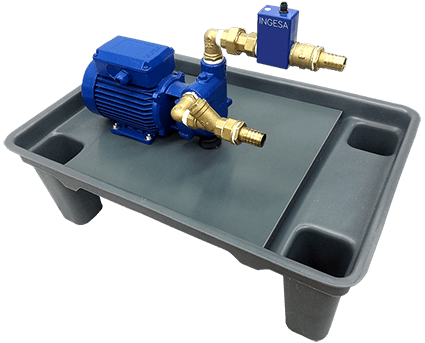

Centrifugal Pumps

Reversible Equipment

THIS EQUIPMENT IS MADE UP OF A CENTRIFUGAL PUMP THAT RECEIVES THE ADDITIVE FROM A TANK AND LEADS HIM TO THE GLASS OF CONTROL. FROM THERE, THE PUMP SUCKS THE LIQUID BACK AND LEADS HIM TO THE MIXER.

THE SET IS ASSEMBLED WITH AN ELECTROVALVE AND A PRESSURE REGULATOR FILTER TO CONTROL THE FLOW BEFORE GOING INSIDE THE PUMP.

ON HIS WAY OUT, THE FLOW IS CONTROLLED BY MEANS OF A FLOWMETER. IT IS ALSO ASSEMBLED WITH THREE CHECK NON-RETURN VALVES TO PREVENT THE BACKFLOW OF THE LIQUID.

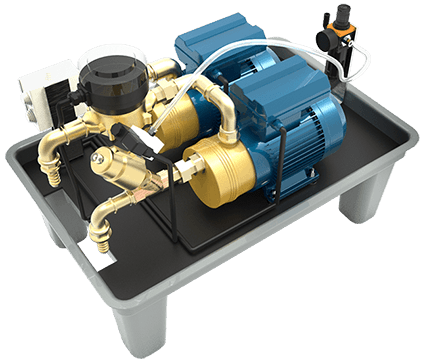

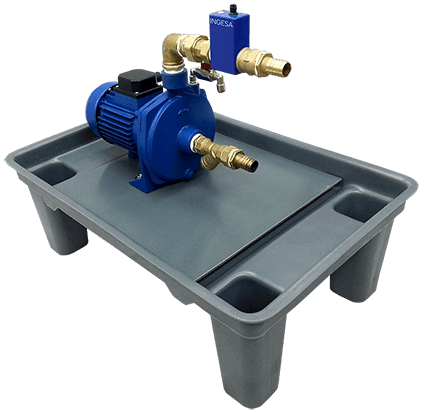

Centrifugal Pumps

Filling and emptying equipment

TWO CENTRIFUGAL PUMPS EQUIPMENT. THE FILLING ONE TAKES THE ADDITIVE FROM A TANK AND LEADS IT TO THE GLASS OF CONTROL. THE EMPTYING SUCKS THE LIQUID FROM THE CONTROL GLASS AND LEADS IT TO THE MIXER.

THE SET IS ASSEMBLED WITH AN ELECTROVALVE AND A PRESSURE REGULATOR FILTER TO CONTROL THE INLET FLOW, AND A FLOW METER TO CONTROL THE OUTLET FLOW.

THE EQUIPMENT IS INTEGRATED WITHIN A BOX OF POLYETHYLENE.

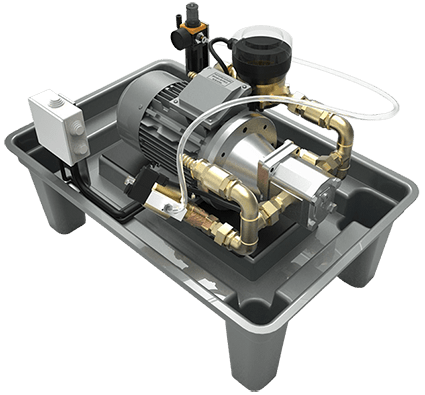

Gear Pumps

Reversible Equipment

THIS EQUIPMENT RECEIVES THE ADDITIVE FROM A TANK AND LEADS IT TO THE CONTROL GLASS, WHERE THE PUMP SUCKS IT BACK AN DIRECTS IT TO THE MIXER.

THE SET IS ASSEMBLED WITH A PRESSURE REGULATOR VALVE, CONTROLLED BY AN ELECTROVALVE AND A PRESSURE REGULATOR FILTER TO CONTROL THE INLET FLOW TO THE PUMP.

THE OUTLET FLOW RATE IS CONTROLLED BY A FLOW METER. IN ADDITION, THE EQUIPMENT IS SUPPLIED WITH THREE NON-RETORN VALVES TO PREVENT THE BACKFLOW OF THE LIQUID.

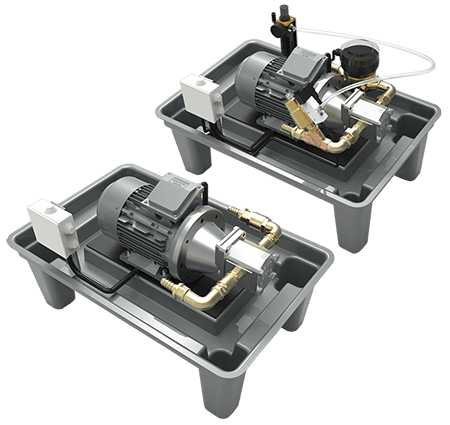

Gear pumps

Filling and Emptying Equipment

THE FILLING EQUIPMENT RECEIVES THE ADDITIVE FROM THE TANK AND DIRECTS IT TO THE CONTROL GLASS. TO CONTROL THE INLET FLOW, IT HAS A PNEUMATIC VALVE OPERATED BY AN ELECTROVALVE AND A PRESSURE REGULATOR FILTER. AT THE OUTLET, THE FLOW RATE IS CONTROLLED BY A FLOW METER.

THE EMPTYING EQUIPMENT SUCKS THE LIQUID FROM THE CONTROL GLASS AND DIRECTS IT TO THE MIXER. AN ANTI-RETURN VALVE IS INSTALLED IN THE OUTLET DUCT TO PREVENT THE REFLUX OF THE LIQUID.

THE TWO SETS ARE ASSEMBLED WITHIN A BOX OF POLYETHYLENE.

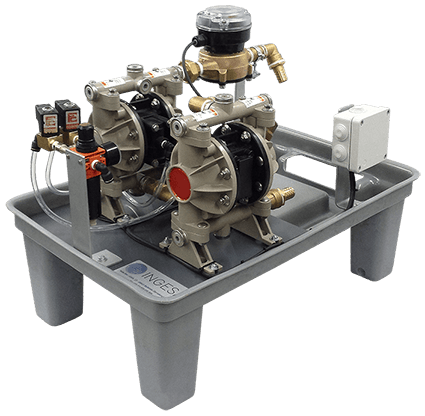

Diaphragm Pumps

½" non-metallic

THE DOUBLE DIAPHRAGM PUMPS USE A DIFFERENTIAL PRESSURE IN THE AIR CHAMBERS TO CREATE ALTERNATELY SUCTION AND POSITIVE PRESSURE OF FLUIDS IN THE CHAMBERS OF FLUIDS.

THE CYCLE OF THE PUMP WILL BEGIN WHEN WE APPLY AIR PRESSURE AND WILL CONTINUE PUMPING BEARING THE REQUIREMENTS.

THE PUMP WILL CREATE AND KEEP THE PREASURE AND WILL STOP THE CYCLE ONCE IT REACHES THE MAXIMUM, RETURNING TO WORK AS NEEDED.

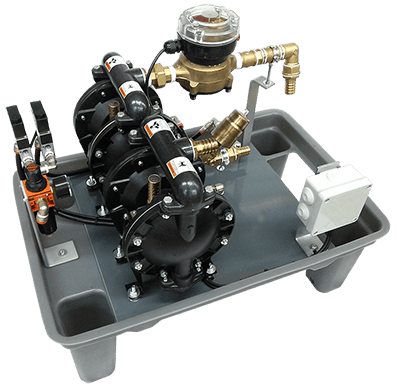

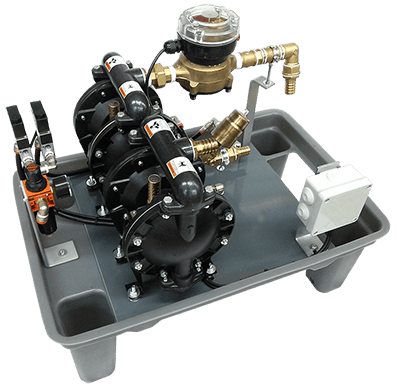

Diaphragm Pumps

1" Metallic

THE CONTROL PANEL GIVES THE ORDER TO START WITH THE CHARGING PROCEDURE, BY OPENING THE FILLING ELECTROVALVE. THIS VALVE STARTS THE FILLING PUMP AND OPENS THE GSR VALVE.

THE LIQUID FLOWS THROUGH THE FLOW METER, WHICH STARTS TO COUNT, AND IS DIRECTED TOWARD THE GLASS OF CONTROL THAT IS FILLED UP TO THE PRE-SELECTED POINT. AT THAT TIME, THE SIGNAL IS GIVEN AND THE PUMP STOPS SUCKING THE LIQUID.

IMMEDIATELY AFTER, THE DRAIN ELECTROVALVE STARTS THE EMPTYING PUMP, WHICH SUCKS THE LIQUID FROM THE GLASS AND POUR IT WHERE IT IS NECESSARY.

Dosing Pumps

Piston-driven

PISTON-DRIVEN PUMPS WITH AN ALTERNATING MOTION. THE FLOW RATE IS ADJUSTABLE, EVEN IN OPERATION, AND MODIFIES THE MOVEMENT OF THE PISTON. THE VARIATION IS LINEAR, ADJUSTABLE FROM 0% TO 100%, AND IS CARRIED OUT MANUALLY BY MEANS OF A HANDLE.

THE CONTROL MECHANISM IS CONSTITUTED BY A SPEED REDUCER, CONSISTING OF A RING GEAR AND WORM SCREW.

THE WHOLE MECHANISM IS LUBRICATED IN AN OIL BATH, WITH ALUMINUM CRANKCASE.

Self-suction Pumps

Liquid Ring

THREE-PHASED OR SINGLE-PHASED MOTOR, 230-380V 50Hz.

MAXIMUM TEMPERATURE: 90°C.

MAXIMUM VISCOSITY: 100 cP.

ACIDITY: 6-9 pH.

MAXIMUM DENSITY: 1 g/cm³.

Centrifugal Pumps

Monoblock

THREE-PHASED OR SINGLE-PHASED MOTOR, 230-380V 50Hz.

MAXIMUM TEMPERATURE: 80°C.

MAXIMUM VISCOSITY: 20 cP.

ACIDITY: 6-8 pH.

MAXIMUM DENSITY: 1 g/cm³.

Volumetric Pumps

Gear-Pumps

THREE-PHASED OR SINGLE-PHASED MOTOR, 230-380V 50Hz.

MAXIMUM TEMPERATURE: 90°C.

MAXIMUM VISCOSITY: 50 cP and 150 cP.

ACIDITY: 5-9 pH.

MAXIMUM DENSITY: 1 g/cm³.